SUPER HINGED FLOAT

SUPER HINGED FLOAT

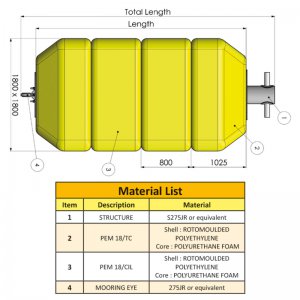

| SIZE | O. D. (mm) | I. D. (mm) | Length (mm) | K (mm) |

|---|---|---|---|---|

| 20HE-DC | 1490 | 946 | 800 | 200 |

| 20HB-DC | 1370 | 799 | 730 | 200 |

| 8HE-DC | 660 | 360 | 550 | 200 |

| WATER DEPTH | 0 - 40 m | 40 - 80 m | ||

|---|---|---|---|---|

| Weight (Kg) | N.B. (Kg) | Weight (Kg) | N.B. (Kg) | |

| 20HE-DC | 134 | 415 | 164 | 385 |

| 20HB-DC | 110 | 330 | 130 | 310 |

| 8HE-DC | 30 | 66 | 34 | 62 |

Floatex Super Hinged Floats are designed to provide buoyancy to submarine hose lines in order to maintain the proper flotation requirement for different style hoses and to guarantee the underwater configuration.

The design of these special floats differ slightly from the standard Hinged Bolted Floats mainly for the engineering of smoothed angles to ensure greater impact resistance in case of lateral crash/friction with a near line of floats.

Another difference is the design of special hole to permit the end user to fit a steel counterweight in case of necessity during the installation.

The floats are composed by two halves made in UV-stabilized linear virgin polyethylene. The Polyethylene used in the manufacturing process is completely recyclable (Eco-Friendly), it's fully compatible with the marine environment, and has a high resistance to UV rays.

Being linear has the advantage that it can be melted and hence repaired by hot fusion welding.

The colour pigment is moulded-in and consequently not added as a coating ensuring greater life of the colour and a big help to the environment as it never requires additional paintings, avoiding toxic dispersions in the water. Floatex polyethylene require a minimal maintenance.

R&D laboratory daily perform test on production samples such as tensile test, hardness test, abrasion test, UV test and Cold temperature test, colour test and other ordinary tests in the aim to ensure the quality and the reliability of Floatex polyethylene.

The floats are filled with closed-cell polyurethane foam with different density in base of the hydrostatic pressure the floats need to withstand. The polyurethane foam ensure great resistance to the leakage of air or water, ensuring unsinkability to the buoy also in case of accidental breaks of the outer shell. The polyurethane foam is 100% made and tested before production by our R&D laboratory.

The two halves are hinged together at one side, and bolted at the other side to ensure optimal clamping with the pipe and facilitate the installation on side even in sub-sea operations. All the metals parts are in AISI 316 stainless steel. All the floats are clearly marked and registered in accordance to current norms and established regulations.

These floats are duly tested in accordance to our internal Quality Control and Quality Assurance procedures, and conforming to GMPHOM specifications and requirements. Test certificates are issued following final test results.

Floatex Hinged Bolted floats are splitted in two main categories in base of the operative water depth, 0-40mt and 40-80mt.

Clearly Floatex floats are able to withstand also deeper water depth upon request of the client.